- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-09-16 Origin: Site

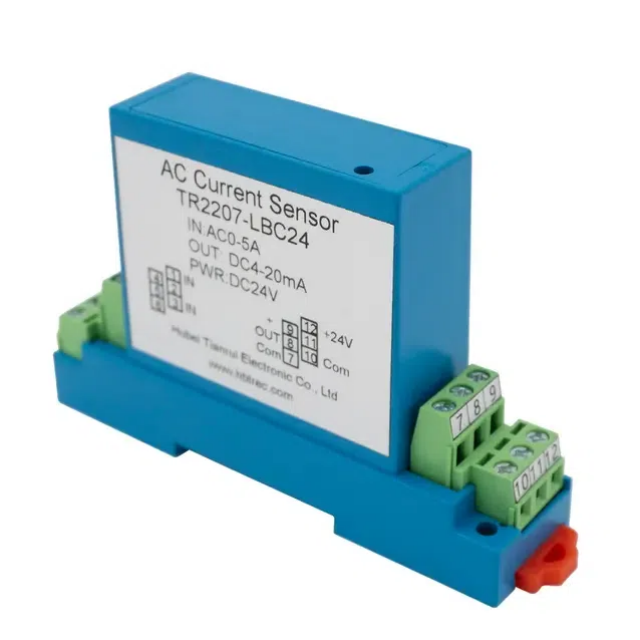

Modern substations demand precise monitoring tools that ensure equipment safety and long-term reliability. A current sensor, particularly a dc leakage current sensor, plays a central role in protecting transformer grounding systems and lightning arrester insulation. By continuously tracking small leakage currents, utilities gain valuable early warnings about insulation degradation or grounding faults that could otherwise result in outages or costly failures. For asset managers and maintenance teams, these sensors are no longer optional but essential components of digital substations. Hubei Tianrui Electronics Co., Ltd. has specialized in developing high-performance current sensors that meet the strict demands of power system monitoring worldwide.

Unlike standard current sensors used mainly in AC applications, a dc leakage current sensor is designed to detect extremely small levels of direct current leakage. These leakages often indicate insulation problems or grounding irregularities in high-voltage equipment. Understanding this distinction is critical because insulation issues often manifest as steady DC drift rather than alternating disturbances.

An AC current sensor typically detects sinusoidal waveforms and is well suited for grid frequency measurements. By contrast, DC leakage detection requires higher sensitivity and a different measurement principle. Since DC signals do not alternate polarity, the sensor must achieve excellent stability, minimal drift, and immunity against environmental changes. Detecting a leakage of only a few microamperes can be the difference between preventing an insulation breakdown and facing an unplanned outage.

Several technologies enable the measurement of DC leakage:

Shunt resistors: Simple and cost-effective but limited by heating and accuracy issues.

Hall-effect sensors: Widely used, providing isolation and good dynamic range for AC/DC current sensing.

Zero-flux current transformers (DC-CTs): Advanced solutions offering exceptional accuracy, very low drift, and strong immunity to external magnetic interference.

For high-reliability substations, zero flux leakage current sensor designs are increasingly chosen because of their stability over long monitoring periods.

When selecting a dc leakage current sensor, engineers should focus on:

Resolution: Ability to detect low-level leakage currents in the microampere range.

Isolation: Safe separation between high-voltage circuits and low-voltage monitoring systems.

Temperature drift: Minimal measurement variation in harsh outdoor environments.

Response time: Adequate speed to capture transient events and leakage spikes.

High-voltage assets such as transformers and surge arresters are at the heart of the power grid. Their reliability depends heavily on healthy insulation and safe grounding. Monitoring leakage currents provides an online, non-intrusive way to track the condition of these assets.

Leakage current analysis reveals a wide range of failure precursors:

Insulation aging caused by thermal stress and electrical loading.

Moisture ingress that lowers insulation resistance over time.

Partial discharge activity that gradually erodes insulation and leads to flashovers.

By monitoring subtle leakage increases, maintenance engineers can act before these failure modes escalate into catastrophic breakdowns.

Consider a power transformer with core grounding connected through a dc leakage current sensor. Over several months, the sensor detects a slow but steady increase in leakage. Instead of waiting for a visible fault, the maintenance team investigates and finds early-stage insulation degradation. Corrective measures are applied, avoiding a costly outage and preserving system stability. This scenario is increasingly common, showing how continuous leakage monitoring directly supports reliability targets.

Establishing an effective online monitoring system requires attention to both sensor placement and data integration. A systematic approach ensures accurate measurements and actionable insights.

Key installation points include:

Transformer grounding terminal to capture core-ground leakage directly.

Arrester ground leads to detect insulation leakage of surge protection devices.

Bushing paths where surface leakage can indicate contamination or degradation.

Proper positioning ensures meaningful leakage signals without interference.

Outdoor substations expose sensors to electromagnetic noise, harmonics, and transient surges. Signal conditioning, including filtering and shielding, is necessary to extract useful leakage data. Using differential inputs and shielded cabling minimizes noise coupling.

Leakage sensors provide valuable data only if it is analyzed over time. A robust monitoring setup should include:

Data loggers capable of high-resolution recording.

Configurable thresholds to trigger alarms when leakage exceeds safe limits.

Integration with SCADA and asset management systems to correlate leakage data with other equipment health indicators.

A dc leakage current sensor is more than a measurement device — it is a frontline defense for transformer grounding systems and arrester insulation health. By integrating a reliable current sensor into substation monitoring, utilities gain early warnings that prevent outages, extend equipment life, and improve overall grid stability. Hubei Tianrui Electronics Co., Ltd. offers advanced solutions tailored for these applications, combining technical excellence with proven industry expertise. To learn more about our product range or request a consultation, please contact us today.