- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Measurement Range: 0.1mA - 1A

Rated Output: 0-7Vrms

Accuracy: ≤0.05% at rated input

Supply Voltage: ±12V

Power Consumption: Max 10mA

Working Frequency: 50 - 400Hz

Operating Temp: -40°C to +85°C

Housing: Waterproof, anti-corrosion metal shell with epoxy resin sealing

| Availability: | |

|---|---|

TRXL-60W

TR

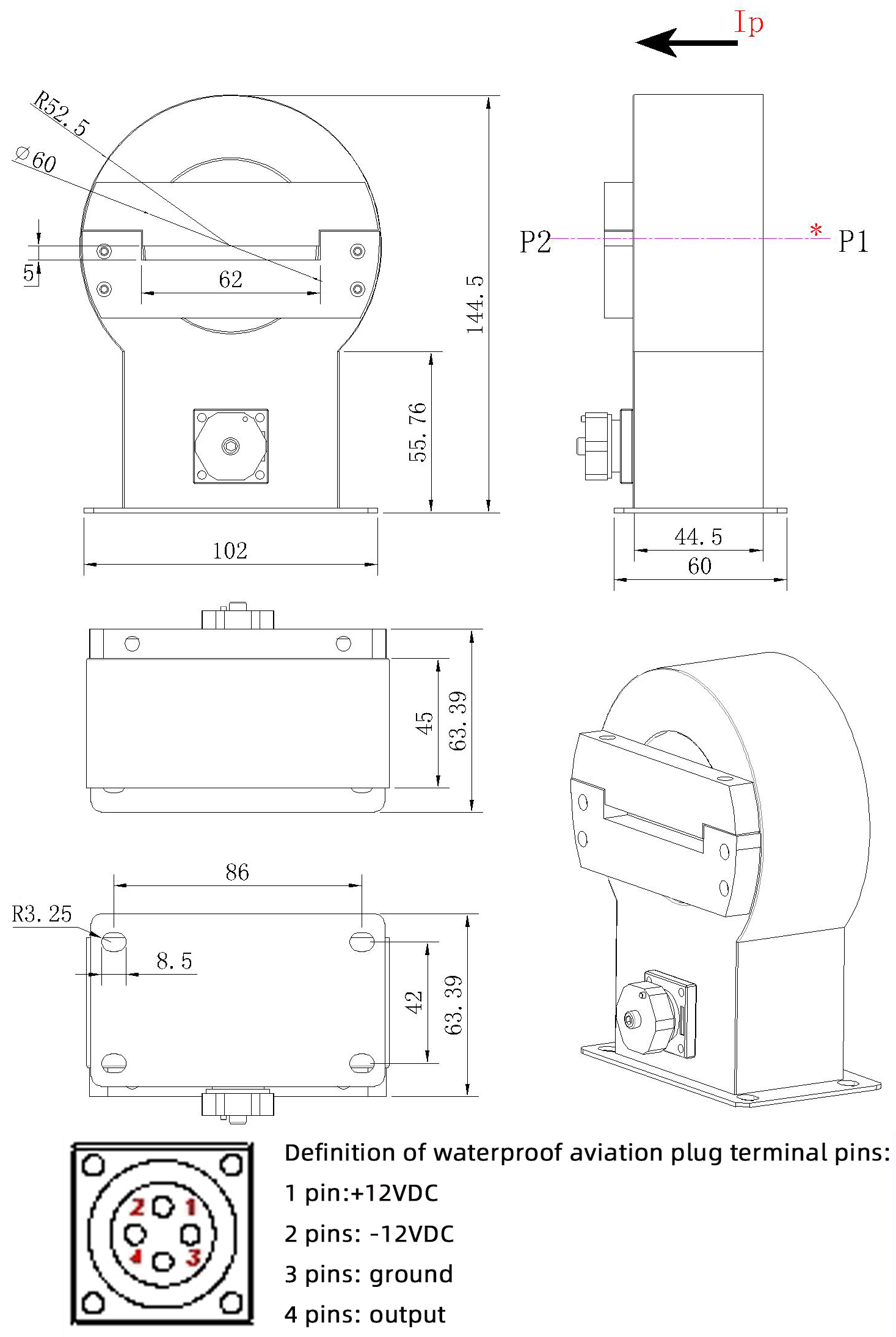

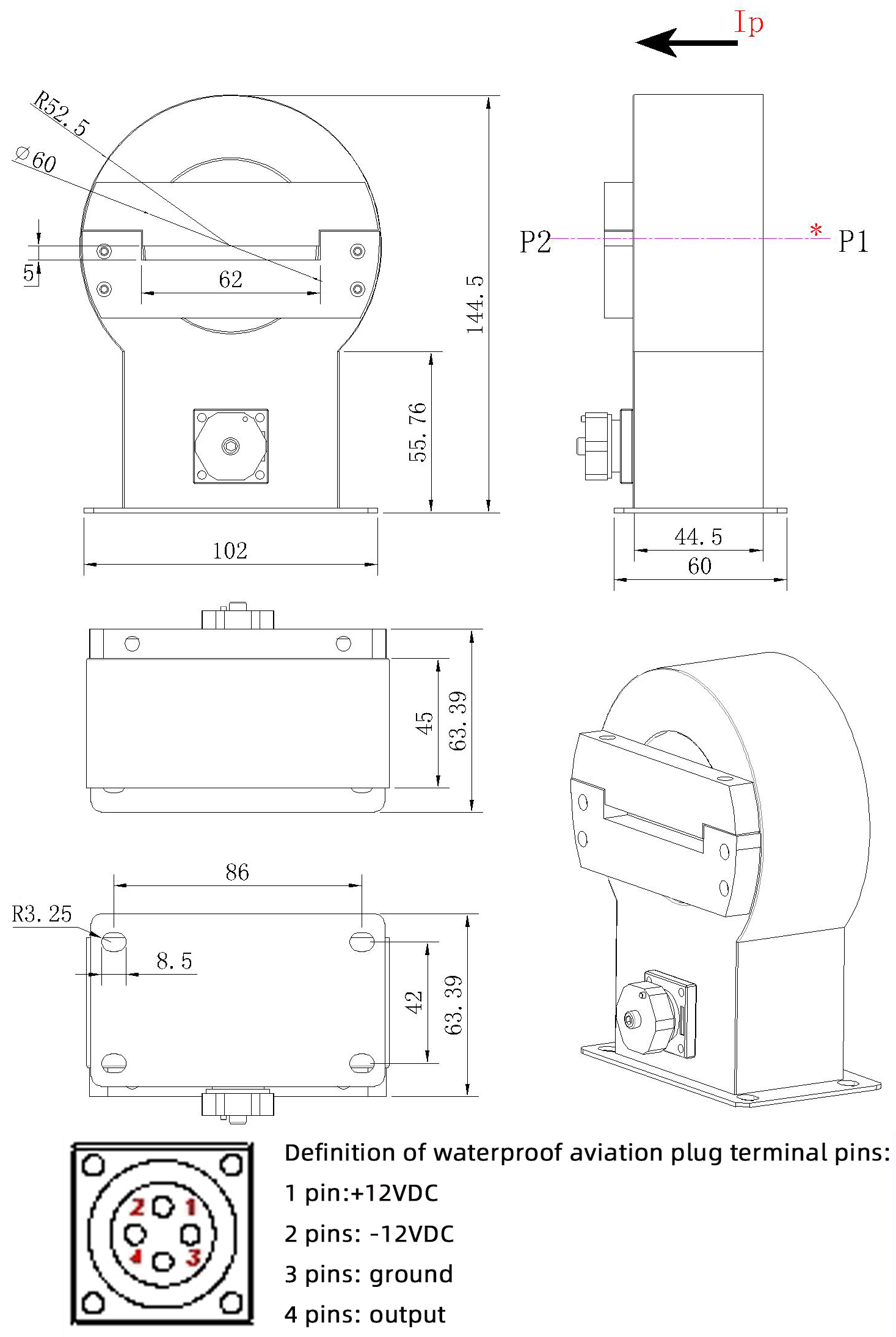

* The structure of copper rows is fastened through the center, and it is suitable for busbar with hole diameter φ60 or copper rows of 55mm×10mm.

* Accurate measurement of μA level current with high measurement accuracy and good linearity.

* Multiple shielding, strong anti-interference ability, can work in complex environments.

* Optional shielded wire or aerial plug outputs are available.

* Special waterproof and anti-corrosion metal shell, epoxy resin sealing and irrigation, can work outdoors for a long time.

* Transformer core grounding on-line monitoring.

* High-voltage bushing insulation on-line monitoring.

* Zinc oxide surge arrester insulation on-line monitoring.

* Current and voltage transformer and capacitor on-line monitoring.

* High-voltage charged display.

Transformer Core Grounding Sensor-TRXL-60W.pdf

Transformer Core Grounding Sensor-TRXL-60W.pdf

Electric | Electrical Symbol | Performance | Opened and closed lock | |

IP | Measurable Range | 0.1mA-1A | ||

VOUT | Rated Output | 0-7Vrms | ||

X | Accuracy @IPN | 0.05% | ||

εL | Linearity | ≤0.05% | ||

Uc | Supply Voltage | ±12V | ||

VOff | Offset Voltage | 1mV | ||

IC | Maximum Power Consumption | 10mA | ||

f | Working Frequency | 50-400 Hz | ||

TA | Operating Temperature | -40℃-+85℃ | ||

TS | Storage Temperature | -40℃-+100℃ | ||

Mechanical | Shell | Metal Shell | Output Mode | Shielded wire/waterproof navigation plug |

Core Material | Nanocrystalline/Permalloy | Seal | Flexible Silicone & Epoxy | |

Magnetic Screen Structure | Carbon Steel/Permalloy | Construction Plan | Base Installation Fixed | |

* The structure of copper rows is fastened through the center, and it is suitable for busbar with hole diameter φ60 or copper rows of 55mm×10mm.

* Accurate measurement of μA level current with high measurement accuracy and good linearity.

* Multiple shielding, strong anti-interference ability, can work in complex environments.

* Optional shielded wire or aerial plug outputs are available.

* Special waterproof and anti-corrosion metal shell, epoxy resin sealing and irrigation, can work outdoors for a long time.

* Transformer core grounding on-line monitoring.

* High-voltage bushing insulation on-line monitoring.

* Zinc oxide surge arrester insulation on-line monitoring.

* Current and voltage transformer and capacitor on-line monitoring.

* High-voltage charged display.

Transformer Core Grounding Sensor-TRXL-60W.pdf

Transformer Core Grounding Sensor-TRXL-60W.pdf

Electric | Electrical Symbol | Performance | Opened and closed lock | |

IP | Measurable Range | 0.1mA-1A | ||

VOUT | Rated Output | 0-7Vrms | ||

X | Accuracy @IPN | 0.05% | ||

εL | Linearity | ≤0.05% | ||

Uc | Supply Voltage | ±12V | ||

VOff | Offset Voltage | 1mV | ||

IC | Maximum Power Consumption | 10mA | ||

f | Working Frequency | 50-400 Hz | ||

TA | Operating Temperature | -40℃-+85℃ | ||

TS | Storage Temperature | -40℃-+100℃ | ||

Mechanical | Shell | Metal Shell | Output Mode | Shielded wire/waterproof navigation plug |

Core Material | Nanocrystalline/Permalloy | Seal | Flexible Silicone & Epoxy | |

Magnetic Screen Structure | Carbon Steel/Permalloy | Construction Plan | Base Installation Fixed | |