- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-10-17 Origin: Site

In industrial automation, precise control and measurement are paramount. Two critical components in this domain are Current to Pressure Transmitters (I/P Transmitters) and Current Transmitter. While both deal with electrical signals, their functions and applications differ significantly.

Working Principle:

An I/P Transmitter converts an electrical current signal (typically 4–20 mA) into a proportional pneumatic pressure. This conversion is essential for controlling pneumatic actuators like control valves and dampers. The device operates using an electromagnetic force balance principle, where a coil produces a magnetic field that moves a flapper valve. This movement modulates airflow through a nozzle, creating backpressure that controls a diaphragm or piston, thereby adjusting the output pneumatic pressure.

Applications:

I/P Transmitters are widely used in industries where pneumatic control is prevalent. Common applications include oil and gas for controlling valves in drilling and refining processes, power generation in regulating steam and gas turbines, chemical processing to maintain precise chemical reactions, water treatment for managing flow rates and pressures, and HVAC systems in controlling dampers and air handling units. These devices are typically mounted on control valves or directly on valve actuators to ensure precise control.

Advantages:

Proportional Control: Provides accurate control over pneumatic actuators

Remote Control Capability: Allows for control over long distances

Compatibility: Easily integrates with existing pneumatic systems

Working Principle:

A Current Transmitter, often referred to as a current sensor or transducer, measures electrical current and converts it into a standardized output signal, such as 4–20 mA or 0–10 V. The device operates based on electromagnetic induction principles, where a change in magnetic flux induces a voltage in a coil. This induced voltage is then processed to produce a proportional output signal.

Applications:

Current Transmitters are essential in applications requiring precise measurement of electrical current. Common uses include electrical distribution systems for monitoring current in circuits, motor protection to detect overcurrent conditions, energy management in measuring current for energy consumption analysis, and renewable energy systems for monitoring current in solar and wind installations. These devices are typically installed in series with the circuit to measure the current flow.

Advantages:

Accurate Measurement: Provides precise current readings

Versatility: Suitable for both AC and DC current measurements

Integration: Easily integrates with digital control systems for monitoring and analysis

| Feature | Current-to-Pressure Transmitter (I/P) | Current Transmitter |

|---|---|---|

| Primary Function | Converts electrical signal to pneumatic pressure | Measures electrical current and converts to standardized signal |

| Output | Pneumatic pressure (e.g., 3–15 psi) | Electrical signal (e.g., 4–20 mA, 0–10 V) |

| Applications | Pneumatic control systems | Electrical measurement and monitoring |

| Operating Principle | Electromagnetic force balance | Electromagnetic induction |

| Signal Type | Pneumatic | Electrical |

| Common Industries | Oil & Gas, Power Generation, Chemical Processing | Electrical Distribution, Energy Management, Renewable Energy |

I/P Transmitter Diagram:

This diagram illustrates the working principle of a Current-to-Pressure Transmitter, showing the conversion of an electrical signal to pneumatic pressure.

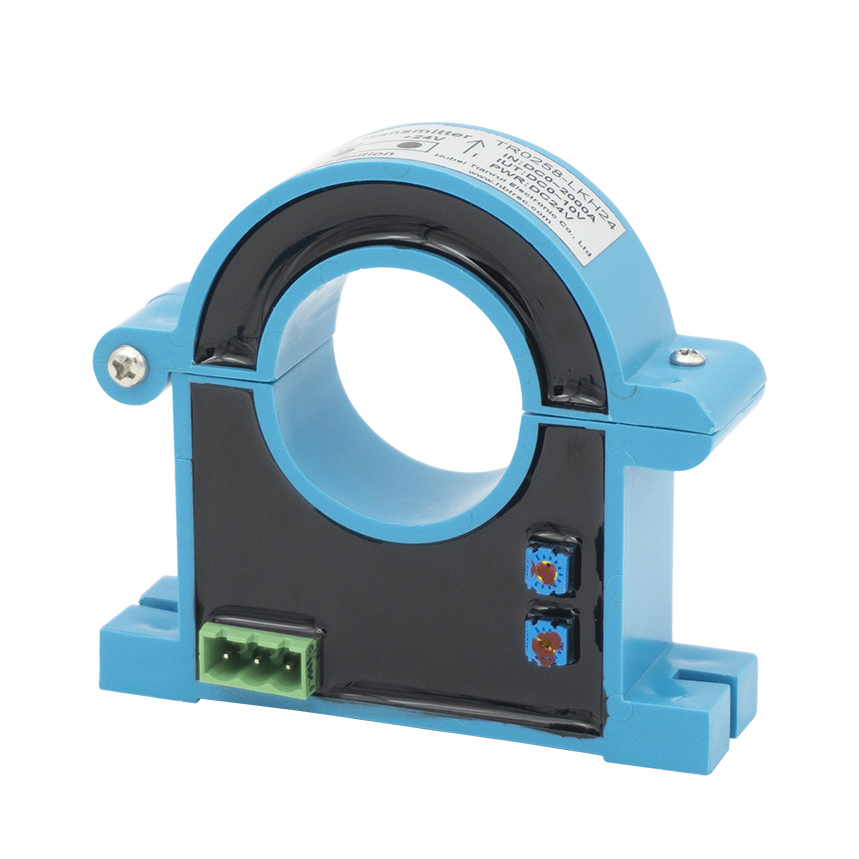

Current Transmitter Example:

This image shows a typical Current Transmitter used for measuring electrical current in circuits.

The evolution of both devices is influenced by advancements in technology and industry needs. Integration with smart systems allows for remote monitoring and diagnostics. Enhanced accuracy and stability have been achieved through advances in materials and design. Digital communication capabilities enable seamless integration with control systems. Miniaturization reduces the size of these devices without compromising performance. Energy efficiency improvements reduce power consumption, contributing to more sustainable operations.

While both Current-to-Pressure Transmitters and Current Transmitters play vital roles in industrial automation, they serve distinct functions. I/P Transmitters are essential for converting electrical signals into pneumatic pressures for controlling actuators, whereas Current Transmitters are crucial for measuring electrical currents and converting them into standardized signals for monitoring and analysis. Understanding their differences and applications ensures the appropriate selection and implementation in various industrial systems.