- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2026-02-12 Origin: Site

Author: Dr. Michael T. Warren, Ph.D., Senior Electrical Engineer and Power Systems Specialist

Qualification: Ph.D. in Electrical Power Engineering, 15+ years working in utility grid measurement systems, published researcher in power instrumentation and monitoring.

Outdoor waterproof current transformers (CTs) are essential components in modern electrical distribution and industrial monitoring systems. Designed for reliable performance in harsh environments, these devices convert high primary currents to standardized, measurable secondary currents while maintaining environmental protection and long-term operational stability. Their practicality and operability have made them indispensable in utility grids, renewable energy installations, and smart monitoring infrastructures worldwide.

A current transformer (CT) is an electromagnetic instrument that steps down large alternating current (AC) to a lower, standardized current (typically 5 A or 1 A) suitable for metering, protection relays, and data acquisition systems. By providing safe electrical isolation and accurate proportional measurement, CTs are the backbone of current sensing in power systems.

Outdoor waterproof CTs are specifically engineered to resist moisture, dust, UV exposure, and temperature extremes. An IP67 or IP65 rating, for example, indicates that the device can withstand immersion in water for short periods and complete dust ingress protection — a necessity when installed on utility poles, outdoor switchgear, or in renewable energy fields.

1. Environmental Resilience and Longevity

Outdoor CTs with IP ratings (e.g., IP67) provide guaranteed protection against rain, humidity, and dust — critical for installations exposed to the elements. The epoxy-filled cores and UV-stable thermoplastics increase lifespan and lower maintenance requirements, especially in areas with frequent weather changes.

2. Flexible Installation

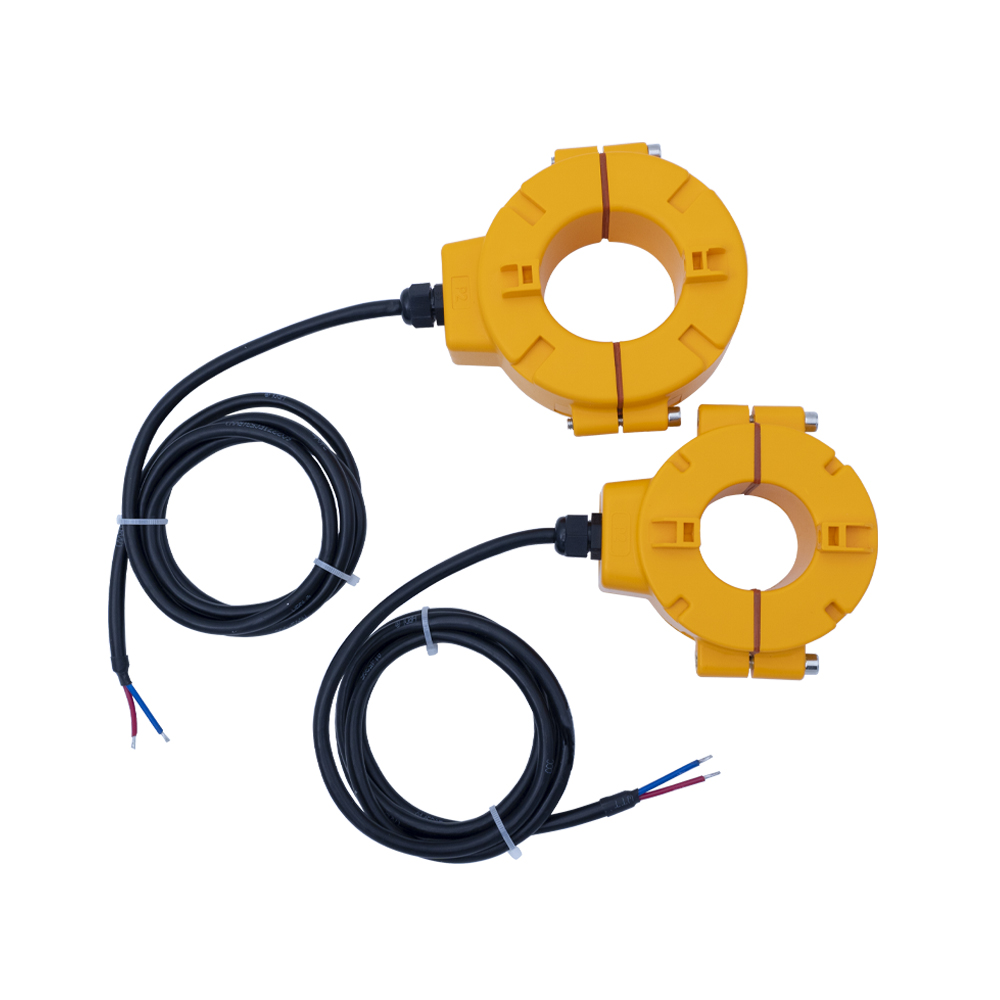

Many outdoor CTs (especially split-core designs) allow installation without interrupting service. This means technicians can attach the CT around existing conductors without power shutdown, significantly reducing operational downtime and safety risks.

3. Wide Applicability Across Power Infrastructure

These CTs are used in:

Utility pole current monitoring

Outdoor distribution transformer metering

Protection and safety systems in substations

Renewable energy plants like solar and wind farms

Smart grids and IoT-enabled monitoring setups

This wide range increases their practical value to multiple sectors.

Outdoor waterproof CTs combine high accuracy classes (0.5–1.0) with rugged mechanical design. Typical features include:

Standardized secondary outputs (1 A or 5 A) for universal compatibility.

Heavy-duty sealed cores that maintain precision in humidity or submersion.

Split-core models that facilitate installation without disconnecting primary conductors.

Textual Data Representation (Simplified):

| Feature | Standard Outdoor CT | Typical Value |

|---|---|---|

| Protection Rating | IP65–IP67 | Waterproof/Dustproof |

| Accuracy Class | IEC 61869-2 compliant | 0.5–1.0 |

| Primary Current Range | Operational | 100 A to 5000 A |

| Output | Sec. Current | 1 A or 5 A |

| Installation | Live / No Shutdown Required | Yes |

Table: Typical Ratings and Operability Factors for Outdoor Waterproof CTs.

“In outdoor current monitoring, waterproof CTs are not just devices — they are data gateways that ensure reliable measurement under environmental stress. Their resilience directly impacts grid safety, energy accounting, and system responsiveness.”

— Prof. Alan R. Jennings, IEEE Senior Member and power measurement expert

This expert view aligns with industry standards such as IEC 61869-2 and IEEE C57.13, which guide design and performance criteria for CTs used in mission-critical applications.

Case: Vietnam Industrial Cloud System Implementation

In an industrial facility in Vietnam, split-core outdoor current transformers were deployed to measure three-phase currents flowing to production lines. The split-core CTs enabled continuous monitoring without disconnecting copper bus bars, significantly reducing installation time and avoiding power interruptions during setup. The sensed currents were integrated into a cloud-based monitoring solution, enabling real-time visibility of power usage across the plant.

Outcome Highlights:

Installation Time Reduced: No power shutdown needed.

Enhanced Data Quality: Continuous current monitoring for each phase.

Cost Savings: Lower labor and downtime costs.

Outdoor waterproof current transformers deliver highly practical, operable, and dependable performance for a variety of outdoor electrical monitoring applications. With robust environmental protection, flexible installation, standardized output signals, and compliance to international standards, they are strategic assets in modern power systems — from utility grids to industrial networks and renewable installations.

The primary difference lies in environmental protection. Outdoor waterproof current transformers are designed with sealed housings, UV-resistant materials, and high IP ratings (typically IP65 or IP67) to withstand rain, humidity, dust, and temperature fluctuations. Indoor CTs generally lack this level of environmental sealing and are intended for controlled environments such as switchboards or electrical cabinets.

Yes, many outdoor CTs—particularly split-core models—are designed for live installation. This allows technicians to clamp the transformer around an existing conductor without disconnecting the circuit. This significantly reduces downtime, labor costs, and operational disruption in industrial or utility environments.

Outdoor waterproof CTs typically comply with IEC 61869-2 or IEEE C57.13 standards and commonly offer accuracy classes of 0.5 or 1.0. High-precision models can achieve even better performance depending on application requirements. Proper installation and correct burden matching are essential to maintain measurement accuracy.