- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-10-16 Origin: Site

Simply put, a current sensor is a device that detects the magnitude of current flowing in a circuit and converts it proportionally into a measurable or processable signal such as voltage, current, or digital output.

Its core functions can be summarized as follows:

Sensing: Detects the current flowing through a conductor.

Isolation: Electrically isolates the high-voltage or high-current primary circuit from the low-voltage measurement circuit for safety.

Conversion: Converts an unmeasurable current into a standard, easy-to-use signal.

A vivid analogy: a current sensor is like a "current scale" or "traffic flow monitor" in an electrical system. It does not block the flow of current, yet it can accurately measure the amount and direction of that flow.

Monitoring current is essential in any electrical or electronic system for several reasons:

Status Monitoring and Protection

Detects motor overloads or locked-rotor conditions.

Monitors for short circuits or overcurrent to trigger protective circuits and prevent damage.

Measures power consumption.

Control and Feedback

In motor drives and inverters, precise current feedback is crucial for advanced control methods such as vector control.

In battery management systems, real-time current monitoring enables smart charging/discharging control and accurate state-of-charge estimation.

Safety Isolation

Directly measuring current in high-voltage circuits can be dangerous. Current sensors provide a non-contact measurement method that isolates the high-voltage side from the safe low-voltage side, ensuring safety for both equipment and personnel.

Current sensors can be categorized according to their working principles as follows:

The simplest and most direct method.

Working Principle: A precision resistor (shunt) with known resistance is connected in series with the load. According to Ohm’s Law (V = I × R), the voltage drop across the resistor is measured to calculate the current.

Advantages: Very low cost, high accuracy, compact size, high bandwidth, no magnetic hysteresis.

Disadvantages:

No isolation between measurement and power circuits.

Power loss and heat generation at high currents (P = I²R), which may affect accuracy.

Typical Applications: Low-side current sensing, battery management, low-power supplies.

The current transformer is a traditional sensor based on the principle of electromagnetic induction.

Working Principle: When alternating current flows through the primary winding (often the conductor itself), an alternating magnetic field is generated in the magnetic core. This induces a proportional current in the secondary winding.

Advantages: Good isolation, moderate cost, capable of measuring large AC currents.

Disadvantages:

Can only measure AC current.

Magnetic saturation limits use in circuits with DC components.

Relatively large size.

Typical Applications: Industrial AC current monitoring, smart meters, AC motor drives.

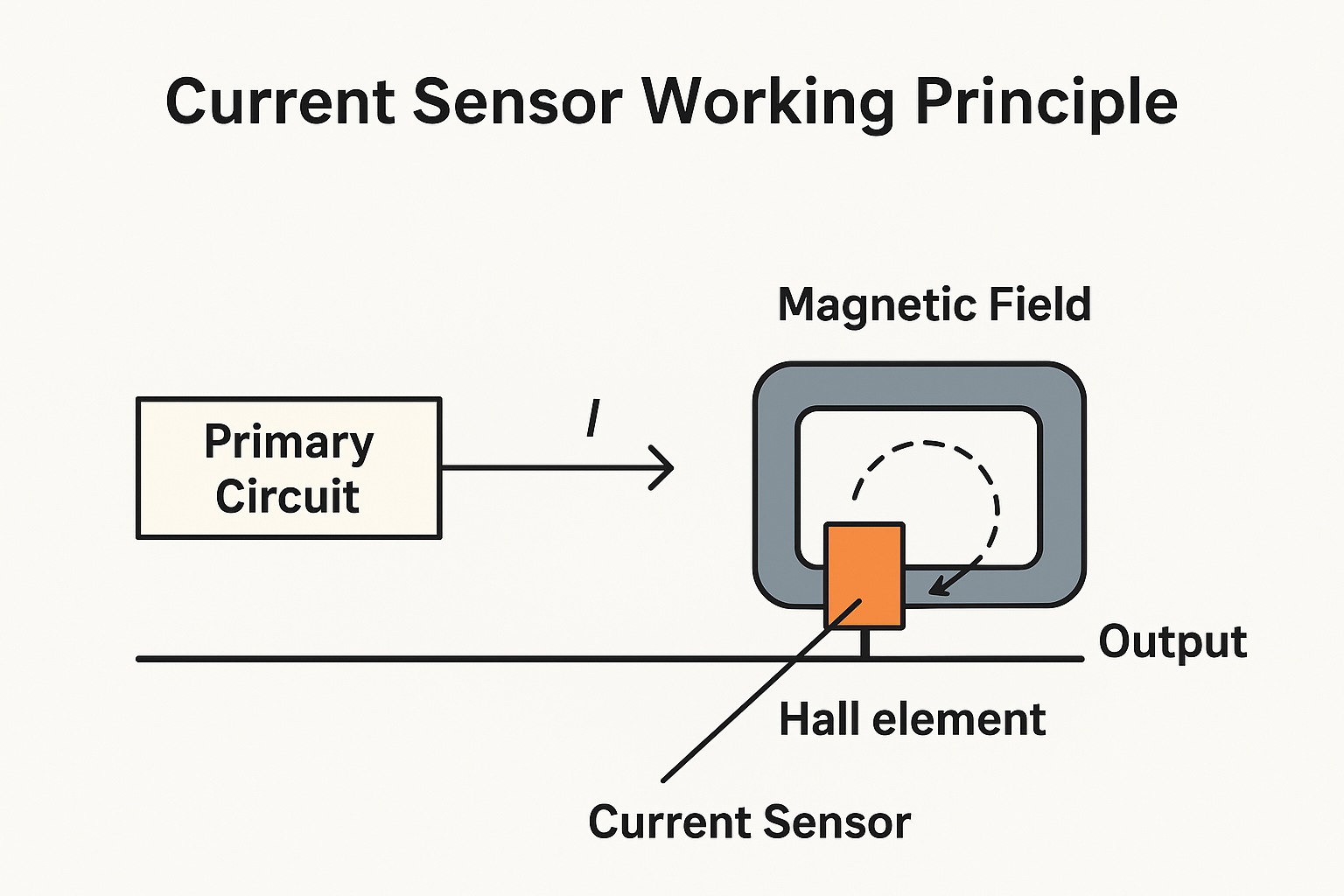

The hall effect sensor is most widely used and mainstream non-contact current sensor today.

Working Principle: Based on the Hall Effect. When a current-carrying conductor is placed in a magnetic field, a voltage (Hall voltage) proportional to both current and magnetic field strength appears across it. Inside the sensor, a magnetic core concentrates the magnetic field generated by the current and directs it to a Hall element. The Hall voltage, after signal conditioning, represents the measured current.

Core Types:

Open-loop type: Simple structure, lower cost, moderate accuracy and thermal drift.

Closed-loop (zero-flux) type: Advanced feedback design. A compensation coil generates an opposite magnetic field that keeps the magnetic flux at zero. The compensation current is precisely proportional to the measured current. High accuracy, excellent linearity, fast response, but higher cost.

Advantages: Measures AC, DC, and pulsed currents; provides electrical isolation; compact size; wide measurement range.

Disadvantages: Temperature drift and offset errors; open-loop accuracy lower than closed-loop.

Typical Applications: Inverters, servo drives, electric vehicles (motor drive, OBC, DC-DC), photovoltaic inverters, UPS systems.

A high-precision magnetic sensing technology.

Working Principle: Utilizes the nonlinear magnetic characteristics of a high-permeability core near saturation to detect extremely small changes in magnetic field, achieving ultra-high accuracy in current measurement.

Advantages: Very high precision, minimal temperature drift and offset, low noise.

Disadvantages: High cost, complex circuitry, higher power consumption.

Typical Applications: High-precision measuring instruments, power quality analyzers, medical equipment.

When choosing a current sensor, consider the following key parameters:

| Parameter | Description |

|---|---|

| Measurement Type | AC, DC, or pulsed current — determines whether a Hall or fluxgate type is needed. |

| Current Range | The maximum and minimum current to be measured. Choose a rated current about 1.5 times higher than the expected maximum. |

| Accuracy | Includes initial error, temperature drift, and offset. Closed-loop Hall and fluxgate sensors offer the highest accuracy. |

| Bandwidth | Frequency range the sensor can accurately respond to; important for drives and switching power supplies. |

| Response Time | The sensor’s reaction speed to current changes. |

| Electrical Isolation | Voltage isolation rating between primary and secondary circuits. |

| Supply Voltage | Operating voltage such as ±12 V, ±15 V, 5 V, or 3.3 V. |

| Output Signal | Voltage, proportional current (e.g., 4–20 mA), or digital (e.g., I²C, SPI). |

| Size and Mounting | Through-hole, PCB-mounted, or terminal type depending on installation space. |

| Sensor Type | Key Features | Typical Applications |

|---|---|---|

| Shunt Resistor | Low cost, no isolation, with power loss | Low-side sensing, battery monitors, consumer electronics |

| Current Transformer | AC only, isolated, medium cost | Industrial meters, AC monitoring, power supplies |

| Hall Effect | AC/DC, isolated, widely used | Inverters, servo drives, EVs, photovoltaics, UPS |

| Fluxgate | Ultra-high precision, low drift, high cost | Laboratory instruments, precision analyzers, medical devices |

In conclusion, the current sensor is a vital component in modern power electronics and automation systems. It serves as the “sensory organ” of electrical control, enabling efficient, safe, and intelligent operation across various industries.