- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

A 0–10mA Core Balance Current Transformer CBCT ( Zero Sequence Current Transformer ZCT) is a precision sensing device designed to detect leakage or residual currents in electrical power systems. It operates by measuring the vector sum of the currents flowing through three-phase conductors. Under normal balanced load conditions, the sum of all phase currents equals zero, and no output signal is generated. When a ground fault, insulation failure, or leakage occurs, an imbalance arises, and the transformer produces a corresponding secondary output signal, typically within the 0–10mA range, proportional to the fault current.

The Zero SequenceCurrent Transformer uses a magnetic core that encircles all phase conductors, enabling non-contact and isolated current detection. It ensures electrical isolation between the monitored circuit and the measurement system, providing both accuracy and safety. The 0–10mA output makes it compatible with various monitoring, protection, and automation devices, such as residual current relays, earth leakage protection modules, and differential protection systems.

With features like high sensitivity, excellent linearity, and wide frequency response, this type of ZCT is suitable for detecting small leakage currents, even below the threshold of conventional overcurrent devices. It can monitor AC, DC, or mixed residual currents, depending on the core material and circuit design.

Typical applications include low-voltage power distribution panels, motor protection systems, photovoltaic and wind power converters, UPS systems, and EV charging stations. In industrial environments, the 0–10mA ZCT plays a crucial role in preventing electrical fires, protecting personnel from electric shock, and ensuring system reliability.

Compact, efficient, and reliable, the 0–10mA Zero SequenceCurrent Transformers is an essential component in modern electrical safety systems. It provides real-time detection and signal transmission for intelligent protection and control equipment, supporting the advancement of smart grid and energy-saving technologies.

Enclosed by epoxy resin, good seismic performance

Perforation method, the hole diameter is from φ12mm-φ260mm, which is convenient for busbar installation

High magnetic permeability material with wide measuring range

Primary Input Current :Iin: 0-5A

Secondary Output Current Io: 0-10mA

Nonlinearity: Precision <±0.2%;

Phase Error<±15'

Frequency : 45-1500Hz

Insulation Resistance: >500mΩ

Power Frequency Withstand Voltage: >3kV

Split-core structure, no need to disconnect the main circuit or remove the cable, can be quickly and easily installed, easy to operate;

The magnetic core winding structural parts are cast with epoxy resin, and the precision-machined core notch end face ensures a perfect fit after closure and good stability;

Adopting high-permeability ultra-microcrystalline core with excellent linearity characteristics and high sensitivity.

The product can be used in electrical fire monitoring system, fire equipment power monitoring system, agricultural network renovation projects, intelligent power system, small current grounding system, electromagnetic relay protection, online environmental protection monitoring and so on. All-round protection of personal and equipment safety, open and close design to adapt to new and old lines, significantly reduce the transformation costs and power outage losses.

| PERFORMANCE | ||||

Electric Performance Parameters | Operating Temperature | -40℃~+70℃ | Relative Humidity | ≤90% |

| Voltage Level | 0.4/0.66/0.72KV | Linear Range | 5%~1000% | |

| Rated Input Current | 0~1A | Rated Frequency | 50/60Hz | |

| Rated Output | 0~0.25mA or 0~1V | Power Frequency Withstand Voltage | 3KV/min | |

| Accuracy Class | 0.5、1.0 | Insulation Strenth | 1000MΩ/500V/min | |

Mechanical Structure Parameters | Shell and Skeleton | PBT/PC Flame Retardant Grade 94-V0 | Output Method | Sheathed Lines |

Iron Core Material | Nanocrystalline | Split-core Structure | “304”Fastening with inseparable screw | |

| Sealing and Filling | Epoxy Resin | Construction Plan | Base mounting screw fixing | |

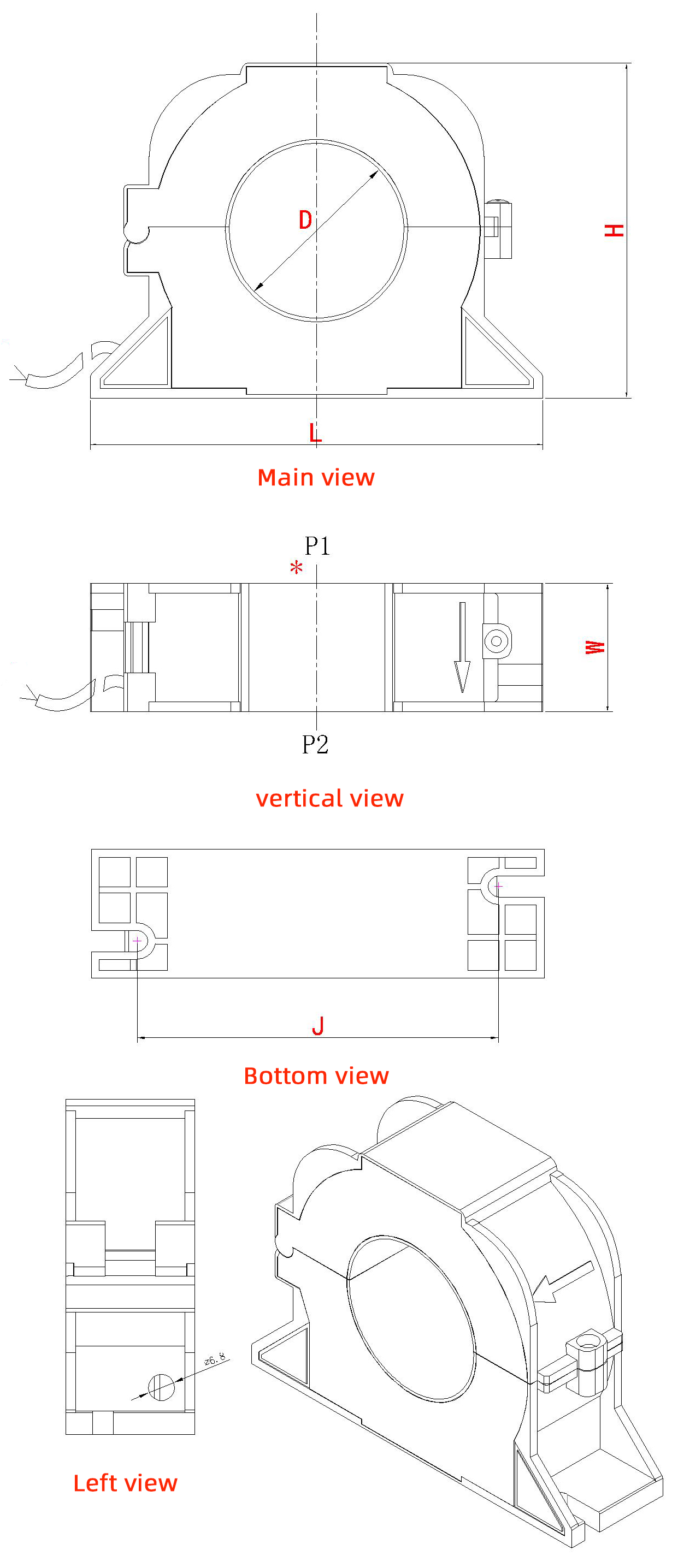

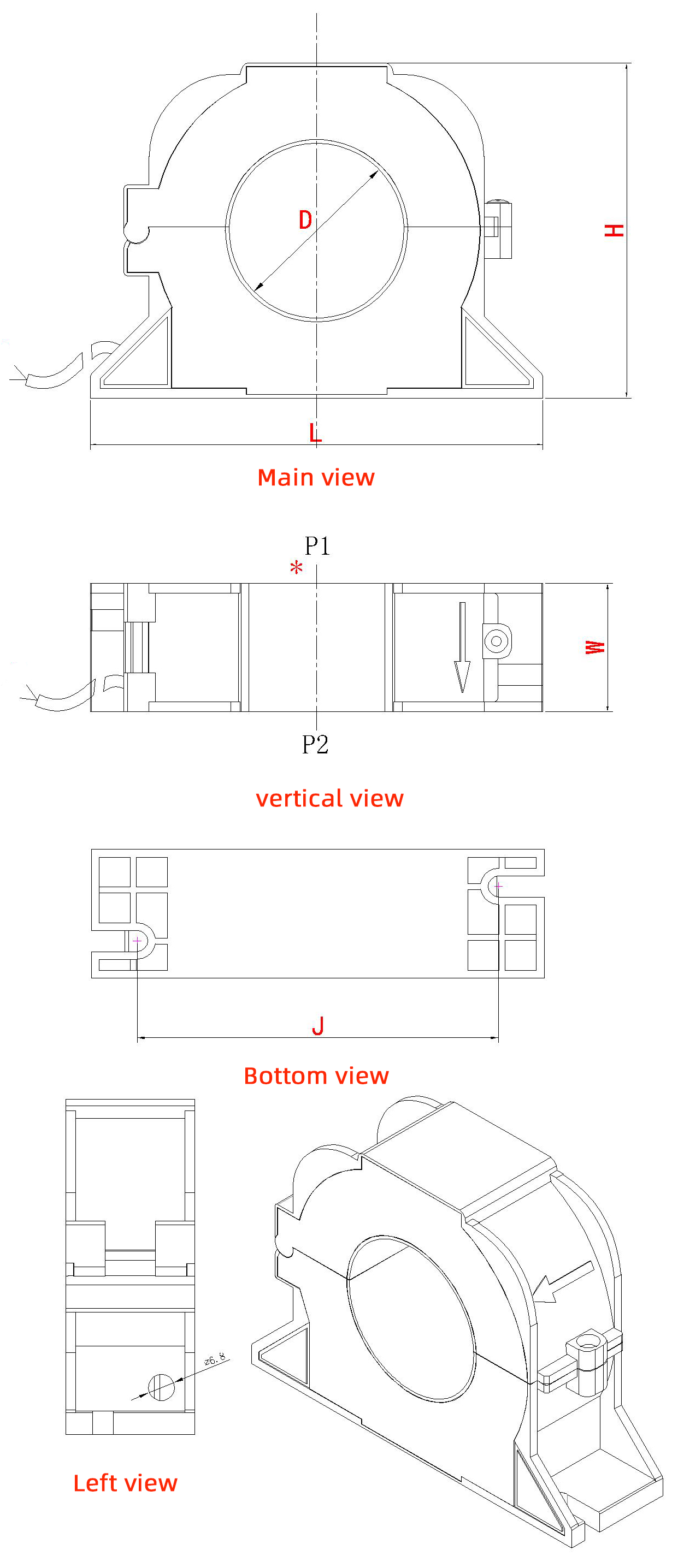

| Product Model NO. | Rated Input | Rated Output | Precision Class | Dimensions(mm) | |||||

| D | L | W | H | J | K | ||||

| TRAK-30B | 0~1A | 0~1A (0.5mA) | 0.5 1.0 | 30 | 88 | 30 | 68 | 76 | M5 |

| TRAK-45B | 45 | 116 | 33 | 86 | 92 | M5 | |||

| TRAK-65B | 65 | 130 | 33 | 105 | 110 | M6 | |||

| TRAK-80B | 80 | 160 | 33 | 128 | 143 | M6 | |||

| TRAK-100B | 100 | 188 | 33 | 154 | 178 | M6 | |||

The live wire and the neutral wire must pass through the core hole of the transformer at the same time;

Before the iron core is closed, ensure that the end face of the incision is clean, free of stains and impurities;

Use a torque wrench (electric/pneumatic) when tightening the screws, and set the torque to a reasonable range.

A 0–10mA Core Balance Current Transformer CBCT ( Zero Sequence Current Transformer ZCT) is a precision sensing device designed to detect leakage or residual currents in electrical power systems. It operates by measuring the vector sum of the currents flowing through three-phase conductors. Under normal balanced load conditions, the sum of all phase currents equals zero, and no output signal is generated. When a ground fault, insulation failure, or leakage occurs, an imbalance arises, and the transformer produces a corresponding secondary output signal, typically within the 0–10mA range, proportional to the fault current.

The Zero SequenceCurrent Transformer uses a magnetic core that encircles all phase conductors, enabling non-contact and isolated current detection. It ensures electrical isolation between the monitored circuit and the measurement system, providing both accuracy and safety. The 0–10mA output makes it compatible with various monitoring, protection, and automation devices, such as residual current relays, earth leakage protection modules, and differential protection systems.

With features like high sensitivity, excellent linearity, and wide frequency response, this type of ZCT is suitable for detecting small leakage currents, even below the threshold of conventional overcurrent devices. It can monitor AC, DC, or mixed residual currents, depending on the core material and circuit design.

Typical applications include low-voltage power distribution panels, motor protection systems, photovoltaic and wind power converters, UPS systems, and EV charging stations. In industrial environments, the 0–10mA ZCT plays a crucial role in preventing electrical fires, protecting personnel from electric shock, and ensuring system reliability.

Compact, efficient, and reliable, the 0–10mA Zero SequenceCurrent Transformers is an essential component in modern electrical safety systems. It provides real-time detection and signal transmission for intelligent protection and control equipment, supporting the advancement of smart grid and energy-saving technologies.

Enclosed by epoxy resin, good seismic performance

Perforation method, the hole diameter is from φ12mm-φ260mm, which is convenient for busbar installation

High magnetic permeability material with wide measuring range

Primary Input Current :Iin: 0-5A

Secondary Output Current Io: 0-10mA

Nonlinearity: Precision <±0.2%;

Phase Error<±15'

Frequency : 45-1500Hz

Insulation Resistance: >500mΩ

Power Frequency Withstand Voltage: >3kV

Split-core structure, no need to disconnect the main circuit or remove the cable, can be quickly and easily installed, easy to operate;

The magnetic core winding structural parts are cast with epoxy resin, and the precision-machined core notch end face ensures a perfect fit after closure and good stability;

Adopting high-permeability ultra-microcrystalline core with excellent linearity characteristics and high sensitivity.

The product can be used in electrical fire monitoring system, fire equipment power monitoring system, agricultural network renovation projects, intelligent power system, small current grounding system, electromagnetic relay protection, online environmental protection monitoring and so on. All-round protection of personal and equipment safety, open and close design to adapt to new and old lines, significantly reduce the transformation costs and power outage losses.

| PERFORMANCE | ||||

Electric Performance Parameters | Operating Temperature | -40℃~+70℃ | Relative Humidity | ≤90% |

| Voltage Level | 0.4/0.66/0.72KV | Linear Range | 5%~1000% | |

| Rated Input Current | 0~1A | Rated Frequency | 50/60Hz | |

| Rated Output | 0~0.25mA or 0~1V | Power Frequency Withstand Voltage | 3KV/min | |

| Accuracy Class | 0.5、1.0 | Insulation Strenth | 1000MΩ/500V/min | |

Mechanical Structure Parameters | Shell and Skeleton | PBT/PC Flame Retardant Grade 94-V0 | Output Method | Sheathed Lines |

Iron Core Material | Nanocrystalline | Split-core Structure | “304”Fastening with inseparable screw | |

| Sealing and Filling | Epoxy Resin | Construction Plan | Base mounting screw fixing | |

| Product Model NO. | Rated Input | Rated Output | Precision Class | Dimensions(mm) | |||||

| D | L | W | H | J | K | ||||

| TRAK-30B | 0~1A | 0~1A (0.5mA) | 0.5 1.0 | 30 | 88 | 30 | 68 | 76 | M5 |

| TRAK-45B | 45 | 116 | 33 | 86 | 92 | M5 | |||

| TRAK-65B | 65 | 130 | 33 | 105 | 110 | M6 | |||

| TRAK-80B | 80 | 160 | 33 | 128 | 143 | M6 | |||

| TRAK-100B | 100 | 188 | 33 | 154 | 178 | M6 | |||

The live wire and the neutral wire must pass through the core hole of the transformer at the same time;

Before the iron core is closed, ensure that the end face of the incision is clean, free of stains and impurities;

Use a torque wrench (electric/pneumatic) when tightening the screws, and set the torque to a reasonable range.