| Availability: | |

|---|---|

TRXLW

TR

Product Features

* Minimal magnetic interference.

* Low temperature drift.

* Fast dynamic response.

* Virtually unaffected by external magnetic fields or conductor positioning.

Product Application

* Industrial Automation and Control.

* Power and Energy Measurement.

* Renewable Energy Systems.

* Electric Vehicle and Charging Systems.

* Laboratory and Testing Equipment:

Product Parameters

Electric Performance | Electrical Symbol | Performance parameters | Small Signal Measurement (Match client circuit) | Large Signal Measurement(Passive) | |

IN | Rated Input | 500mARMS | 10ARMS | ||

IP | Measurable Range | 0.1mA-1A | 0.1-20A | ||

IOUT | Rated Output | 10mARMS | 10mARMS | ||

X | Accuracy@IPN | 0.05% | 0.20% | ||

εL | Linearity | ≤0.05% | ≤0.2% | ||

Uc | Supply Voltage | Client Circuit Customization | / | ||

VOff | Offset Voltage | 1mV | / | ||

IC | Max Power Consumption | 10mA | / | ||

f | Operating Frequency | 50-400 Hz | |||

TA | Operating Temperature | -40℃ ~ +85℃ | |||

TS | Storage Temperature | -40℃ ~ +100℃ | |||

Mechanical Structure | Shell | Metal Shell | Output Mode | Socket block/shielded wire | |

Metal Core Material | Nanocrystalline/Permalloy | Seal | Flexible Silicone & Epoxy | ||

Magnetic Screen Structure | Carbon Steel/Permalloy | Construction Plan | Base Installation Fixed | ||

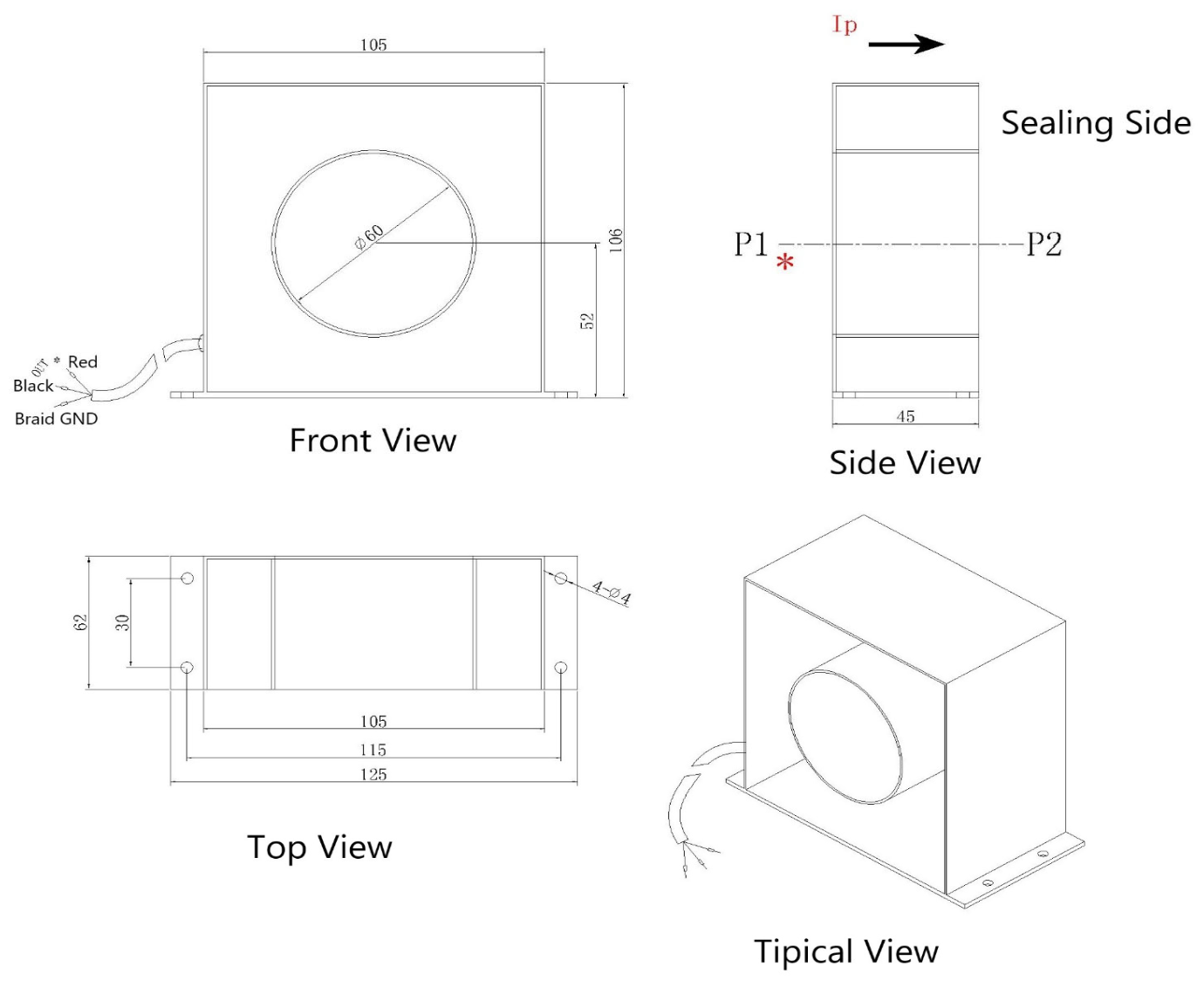

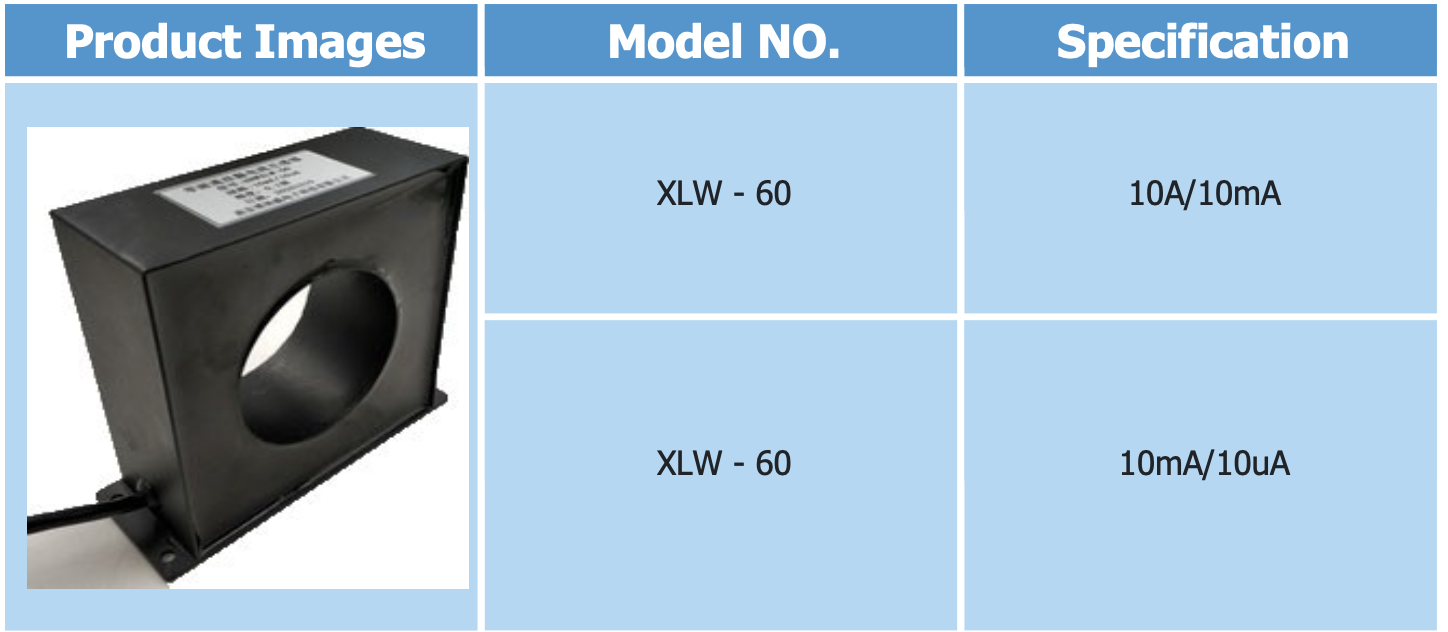

Main specification and Drawing

Note: can be customized according to customer requirements (through hole diameter, external dimensions, parameter transformation ratio)

Product Features

* Minimal magnetic interference.

* Low temperature drift.

* Fast dynamic response.

* Virtually unaffected by external magnetic fields or conductor positioning.

Product Application

* Industrial Automation and Control.

* Power and Energy Measurement.

* Renewable Energy Systems.

* Electric Vehicle and Charging Systems.

* Laboratory and Testing Equipment:

Product Parameters

Electric Performance | Electrical Symbol | Performance parameters | Small Signal Measurement (Match client circuit) | Large Signal Measurement(Passive) | |

IN | Rated Input | 500mARMS | 10ARMS | ||

IP | Measurable Range | 0.1mA-1A | 0.1-20A | ||

IOUT | Rated Output | 10mARMS | 10mARMS | ||

X | Accuracy@IPN | 0.05% | 0.20% | ||

εL | Linearity | ≤0.05% | ≤0.2% | ||

Uc | Supply Voltage | Client Circuit Customization | / | ||

VOff | Offset Voltage | 1mV | / | ||

IC | Max Power Consumption | 10mA | / | ||

f | Operating Frequency | 50-400 Hz | |||

TA | Operating Temperature | -40℃ ~ +85℃ | |||

TS | Storage Temperature | -40℃ ~ +100℃ | |||

Mechanical Structure | Shell | Metal Shell | Output Mode | Socket block/shielded wire | |

Metal Core Material | Nanocrystalline/Permalloy | Seal | Flexible Silicone & Epoxy | ||

Magnetic Screen Structure | Carbon Steel/Permalloy | Construction Plan | Base Installation Fixed | ||

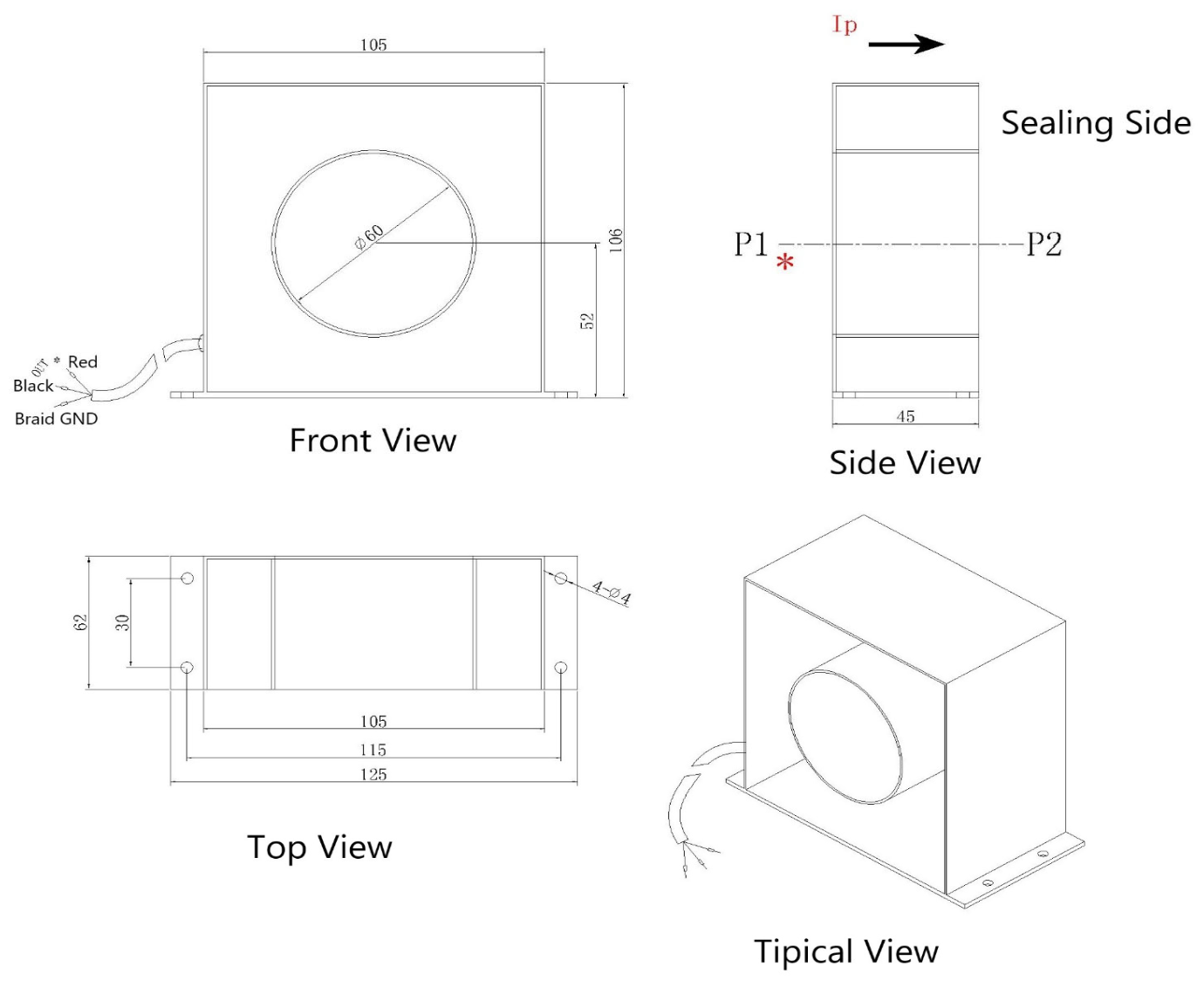

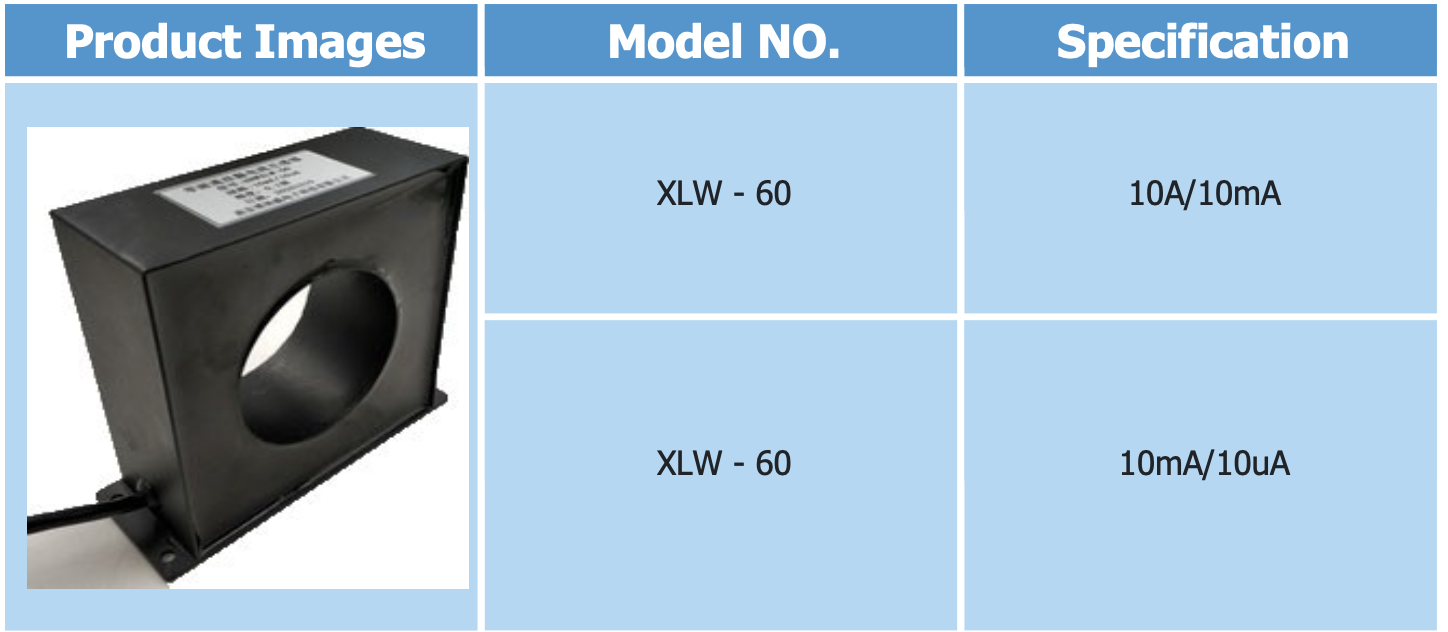

Main specification and Drawing

Note: can be customized according to customer requirements (through hole diameter, external dimensions, parameter transformation ratio)