- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

TRHF

TR

Product Features

* Good linearity and high precision; fast response speed, which can reach ns level.

* Frequency bandwidth, can work in the range of 100kHz-50MHz.

* Opened and closed structure, easy to install.

* The waterproof level can reach IP68, which can be used indoors and outdoors.

Product Application

Partial discharge online monitoring system, SF6 circuit breakers of various voltage levels, gas-insulated combined electrical appliances (GIS) equipment, cabinet switches, column switches, transformer equipment and primary high-voltage transformers.

Download Size Sheet

High-frequency Partial Discharge Monitoring Sensor.pdf

High-frequency Partial Discharge Monitoring Sensor.pdf

Product Parameters

Type | TRHF-60 | |

F | Operating Frequency Range | 0.1MHz-50MHz |

S | Sensitivity | 5pC |

ZC | Transmission Impedance | 12mV/mA |

RM | Matched Impedance | 50Ω |

TA | Operating Temperature | -40℃-+85℃ |

TS | Storage Temperature | -40℃-+100℃ |

Output Interface | BNC socket or RG5850-3/SMA copper coaxial cable | |

P | Protection Class | IP68 |

Φ | Bore Diameter | Φ60mm |

W | Weight | Around 1.1kg |

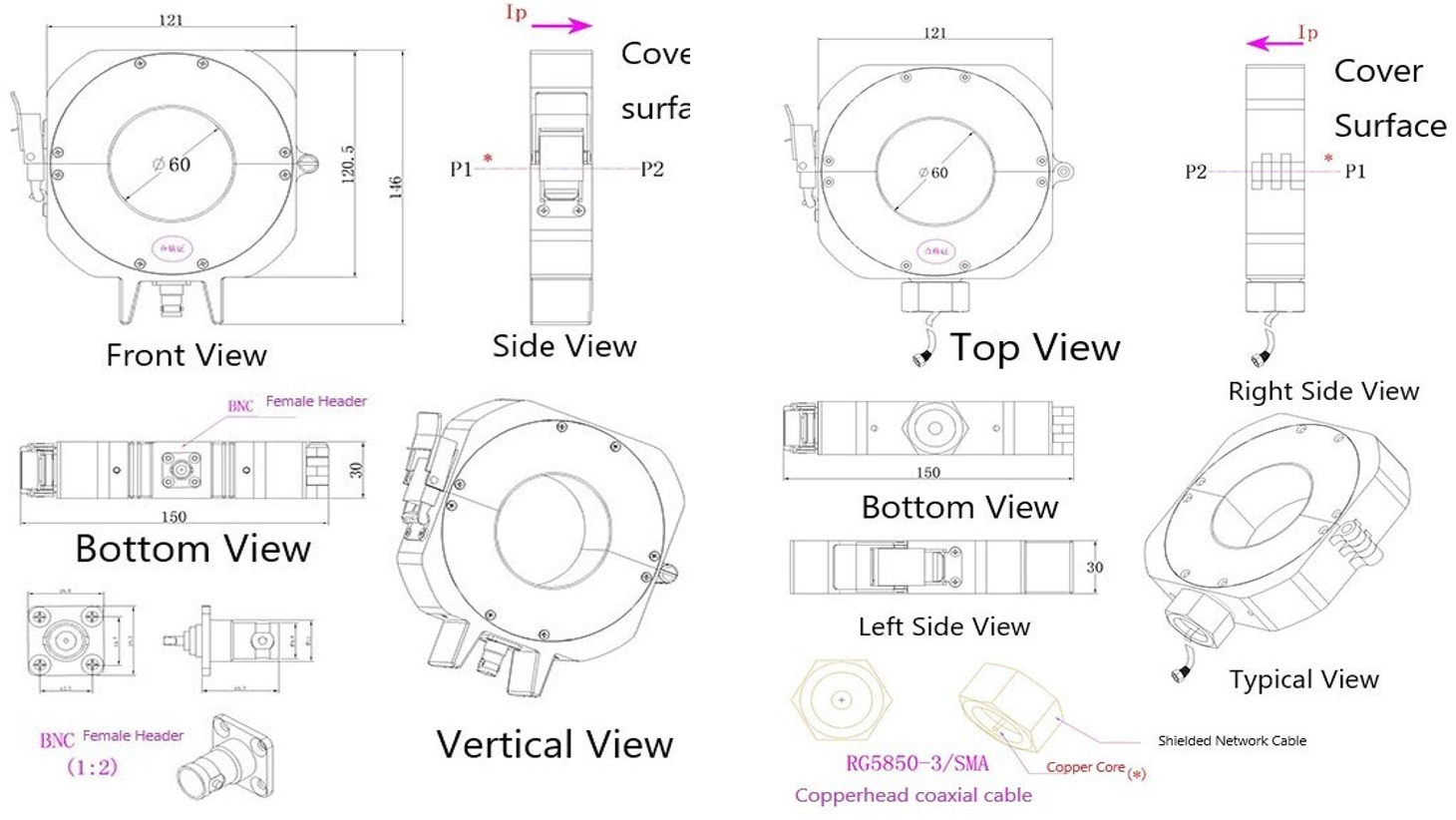

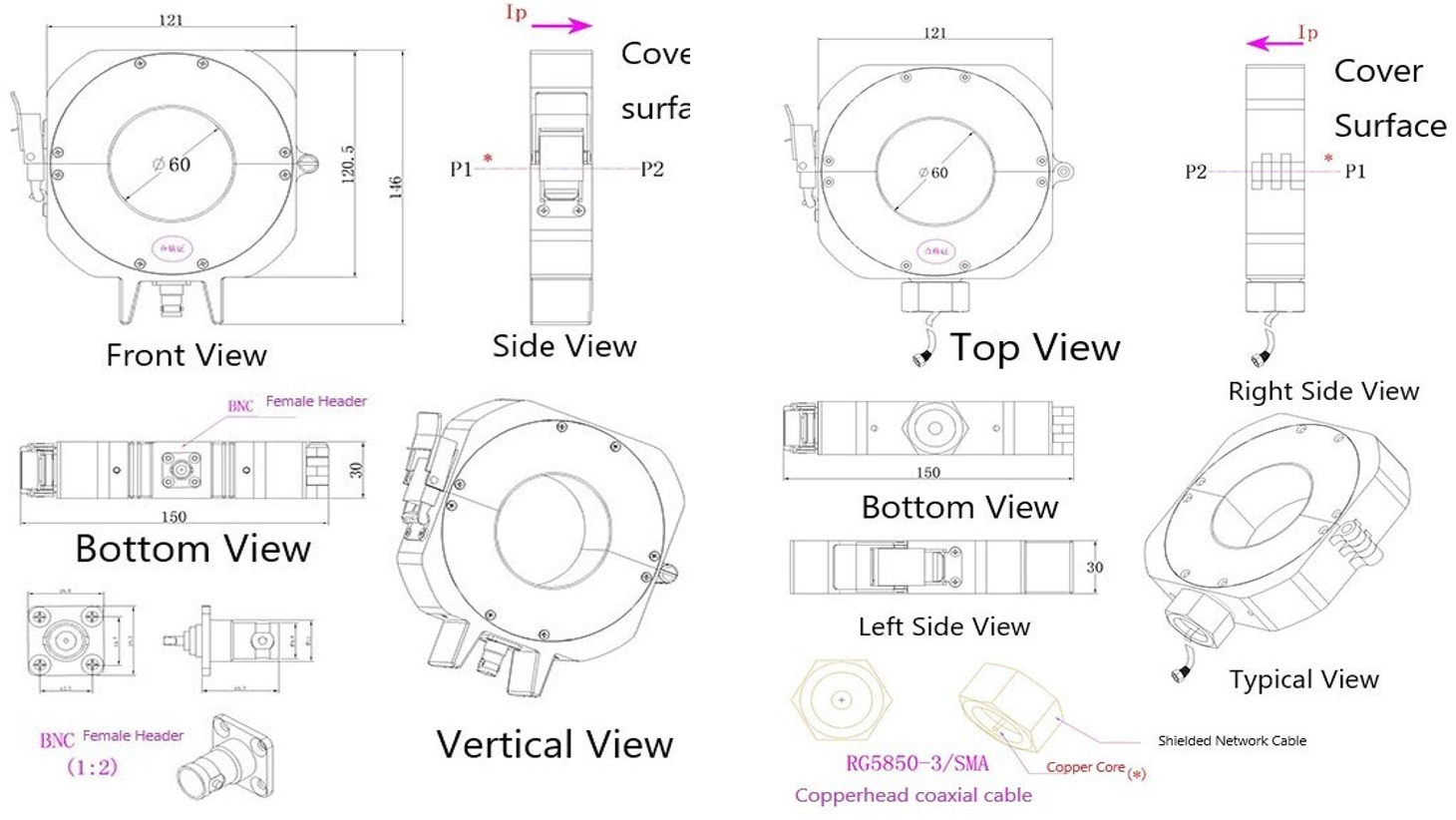

Dimension and Connection

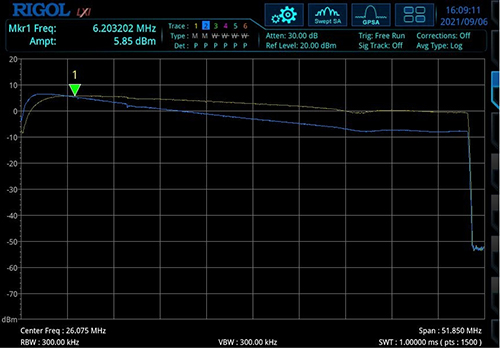

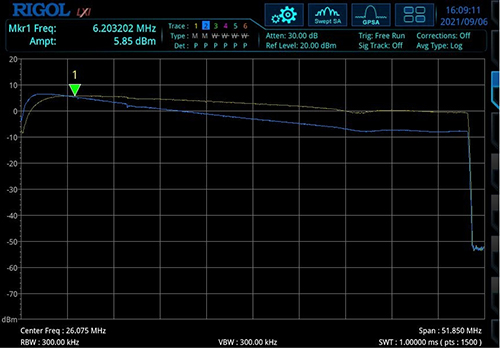

Amplitude-frequency Characteristics

Product Features

* Good linearity and high precision; fast response speed, which can reach ns level.

* Frequency bandwidth, can work in the range of 100kHz-50MHz.

* Opened and closed structure, easy to install.

* The waterproof level can reach IP68, which can be used indoors and outdoors.

Product Application

Partial discharge online monitoring system, SF6 circuit breakers of various voltage levels, gas-insulated combined electrical appliances (GIS) equipment, cabinet switches, column switches, transformer equipment and primary high-voltage transformers.

Download Size Sheet

High-frequency Partial Discharge Monitoring Sensor.pdf

High-frequency Partial Discharge Monitoring Sensor.pdf

Product Parameters

Type | TRHF-60 | |

F | Operating Frequency Range | 0.1MHz-50MHz |

S | Sensitivity | 5pC |

ZC | Transmission Impedance | 12mV/mA |

RM | Matched Impedance | 50Ω |

TA | Operating Temperature | -40℃-+85℃ |

TS | Storage Temperature | -40℃-+100℃ |

Output Interface | BNC socket or RG5850-3/SMA copper coaxial cable | |

P | Protection Class | IP68 |

Φ | Bore Diameter | Φ60mm |

W | Weight | Around 1.1kg |

Dimension and Connection

Amplitude-frequency Characteristics

content is empty!

content is empty!