- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

A Closed Loop Residual Zero Sequence Current Transformer (RZCT) is a highly precise current sensing device designed to detect leakage or residual currents in three-phase power systems. Unlike conventional current transformers that measure phase currents individually, the RZCT measures the vector sum of all phase currents passing through its core. Under normal balanced conditions, the sum of the three-phase currents is zero. However, if an insulation fault, leakage, or ground fault occurs, an unbalanced residual current is generated, which the RZCT accurately detects and converts into a proportional output signal.

This closed-loop design operates based on the zero-flux principle, using a feedback control circuit and a compensation winding to maintain zero magnetic flux inside the core. When residual current flows through the primary conductors, a magnetic field is produced in the core. The secondary circuit generates an opposing magnetic field through the compensation coil to cancel it out. The current flowing in this compensation coil is directly proportional to the measured residual current, ensuring exceptional linearity, fast response, and high accuracy even at low current levels.

The closed-loop RZCT provides excellent temperature stability, low offset, and minimal phase shift compared to open-loop types, making it ideal for use in ground fault protection, differential protection, residual current detection, and insulation monitoring in industrial, power distribution, and renewable energy systems.

Typical applications include low-voltage switchgear, motor protection, photovoltaic inverters, and electric vehicle charging systems. Its compact structure, high sensitivity, and wide dynamic range make it suitable for both AC and DC residual current monitoring.

In modern electrical safety systems, the Closed Loop Residual Zero Sequence Current Transformer plays a vital role in detecting leakage faults quickly and accurately, ensuring equipment reliability and personnel safety in critical power networks.

Product Features

* Flexible output mode, socket or lead output;

* A variety of core hole diameter options, the hole diameter is from φ12mm to φ260mm;

* Casting with epoxy resin, good stability;

* Adopt high magnetic permeability nickel steel or nanocrystalline magnetic core, with good linearity and high sensitivity .

* Excellent balance characteristics, with strong anti-electromagnetic interference ability.

Scope of Application

Suitable for motor protection, electromagnetic relay protection device, microcomputer protection device; electrical

fire monitoring, fire leakage system, low current grounding system.

Electric Performance Parameters | Operating Temperature | -40℃~+70℃ | Relative Humidity | ≤90% |

Voltage Level | 0.4/0.66/0.72kV | Linear Range | 5%~120% | |

Rated Input Current (AC) | 10mA~5A | Working Frequency | 45~1250Hz | |

Rated Output (AC) | 0~1V or 0~5mA | Medium Strength: | 3000Vac/min | |

Accuracy Class | 0.5、1.0、2.0 | Insulation Resistance | >500 M Ohms/500Vdc | |

Mechanical Structure Parameters | Shell Material | PBT/PC Flame Retardant Grade 94- V0 | Output Method | Socket or Shielded Sheathed Wire |

Iron Core Material | Nickel Steel or Ultra Microcrystalline | construction plan | Base installation bolts are fixed | |

Sealing and Filling | Epoxy Resin | Environmental Requirements | Meet RoHS |

Typical Value of Main Products

Model NO. | Input current rated Value AC | Rated Continuous Thermal Current AC | Common Transformation Ratio | Accuracy Class | Secondary Load(Ohms ) | Dimensions(mm) | |

ApertureD | other size | ||||||

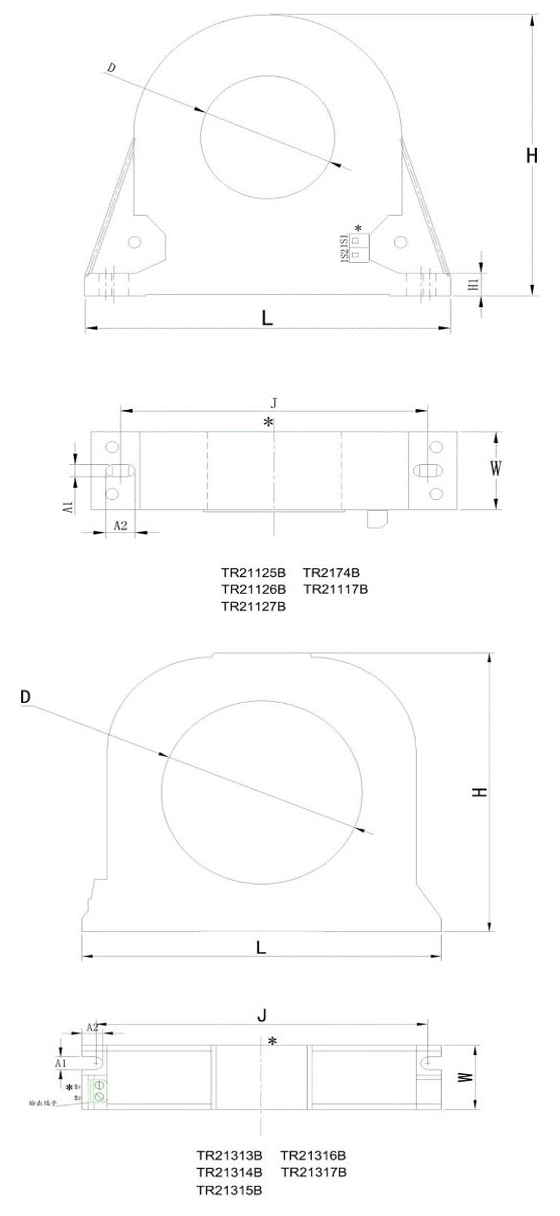

TR21125B | 10mA~5A | 10A | 1000:1 2000:1 | 0.2,0.5 | ≤200 | 25 | L-W-H-J-A1-A2 80-22-69.5-68- 5.2-8 |

TR21126B | 10mA~5A | 10A | 1000:1 2000:1 | 0.2,0.5 | ≤500 | 45 | L-W-H-J-A1-A2 120-33-101.5- 98-5.2-8.5 |

TR21127B | 10mA~5A | 10A | 1000:1 2000:1 | 0.2,0.5 | ≤500 | 55 | L-W-H-J-A1-A2 150-35-126- 126-5.2-12 |

TR2174B | 10mA~5A | 10A | 1000:1 2000:1 | 0.2,0.5 | ≤500 | 35 | L-W-H-J-A1-A2 100-30-90- 83.5-5.2-9.5 |

TR21313B | 10mA~5A | 10A | 1000:1 2000:1 | 0.2,0.5 | ≤500 | 32 | L-W-H-J-A1-A2 91-28-70-80- 5.5-7.5 |

TR21314B | 10mA~5A | 10A | 1000:1 2000:1 | 0.2,0.5 | ≤500 | 45 | L-W-H-J-A1-A2 104-28-83-93- 5.5-7.5 |

TR21315B | 10mA~5A | 10A | 1000:1 2000:1 | 0.2,0.5 | ≤500 | 65 | L-W-H-J-A1-A2 126-28-105- 115-5.5-7.5 |

TR21316B | 10mA~5A | 10A | 1000:1 2000:1 | 0.2,0.5 | ≤500 | 80 | L-W-H-J-A1-A2 143-28-122- 132-5.5-7.5 |

TR21317B | 10mA~5A | 10A | 1000:1 2000:1 | 0.2,0.5 | ≤500 | 105 | L-W-H-J-A1-A2 172-28-151- 161-5.5-7.5 |

TR21117B | 10mA~5A | 10A | 1000:1 2000:1 | 0.2,0.5 | ≤500 | 72 | L-W-H-J-A1-A2 175-42-150- 150-6.2-13 |

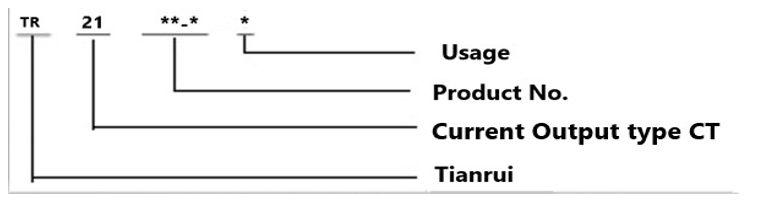

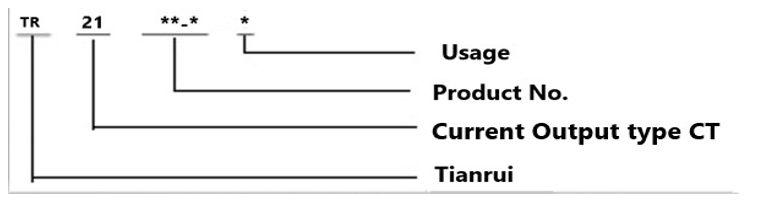

Outline Structure Diagram (Unit :mm)

A Closed Loop Residual Zero Sequence Current Transformer (RZCT) is a highly precise current sensing device designed to detect leakage or residual currents in three-phase power systems. Unlike conventional current transformers that measure phase currents individually, the RZCT measures the vector sum of all phase currents passing through its core. Under normal balanced conditions, the sum of the three-phase currents is zero. However, if an insulation fault, leakage, or ground fault occurs, an unbalanced residual current is generated, which the RZCT accurately detects and converts into a proportional output signal.

This closed-loop design operates based on the zero-flux principle, using a feedback control circuit and a compensation winding to maintain zero magnetic flux inside the core. When residual current flows through the primary conductors, a magnetic field is produced in the core. The secondary circuit generates an opposing magnetic field through the compensation coil to cancel it out. The current flowing in this compensation coil is directly proportional to the measured residual current, ensuring exceptional linearity, fast response, and high accuracy even at low current levels.

The closed-loop RZCT provides excellent temperature stability, low offset, and minimal phase shift compared to open-loop types, making it ideal for use in ground fault protection, differential protection, residual current detection, and insulation monitoring in industrial, power distribution, and renewable energy systems.

Typical applications include low-voltage switchgear, motor protection, photovoltaic inverters, and electric vehicle charging systems. Its compact structure, high sensitivity, and wide dynamic range make it suitable for both AC and DC residual current monitoring.

In modern electrical safety systems, the Closed Loop Residual Zero Sequence Current Transformer plays a vital role in detecting leakage faults quickly and accurately, ensuring equipment reliability and personnel safety in critical power networks.

Product Features

* Flexible output mode, socket or lead output;

* A variety of core hole diameter options, the hole diameter is from φ12mm to φ260mm;

* Casting with epoxy resin, good stability;

* Adopt high magnetic permeability nickel steel or nanocrystalline magnetic core, with good linearity and high sensitivity .

* Excellent balance characteristics, with strong anti-electromagnetic interference ability.

Scope of Application

Suitable for motor protection, electromagnetic relay protection device, microcomputer protection device; electrical

fire monitoring, fire leakage system, low current grounding system.

Electric Performance Parameters | Operating Temperature | -40℃~+70℃ | Relative Humidity | ≤90% |

Voltage Level | 0.4/0.66/0.72kV | Linear Range | 5%~120% | |

Rated Input Current (AC) | 10mA~5A | Working Frequency | 45~1250Hz | |

Rated Output (AC) | 0~1V or 0~5mA | Medium Strength: | 3000Vac/min | |

Accuracy Class | 0.5、1.0、2.0 | Insulation Resistance | >500 M Ohms/500Vdc | |

Mechanical Structure Parameters | Shell Material | PBT/PC Flame Retardant Grade 94- V0 | Output Method | Socket or Shielded Sheathed Wire |

Iron Core Material | Nickel Steel or Ultra Microcrystalline | construction plan | Base installation bolts are fixed | |

Sealing and Filling | Epoxy Resin | Environmental Requirements | Meet RoHS |

Typical Value of Main Products

Model NO. | Input current rated Value AC | Rated Continuous Thermal Current AC | Common Transformation Ratio | Accuracy Class | Secondary Load(Ohms ) | Dimensions(mm) | |

ApertureD | other size | ||||||

TR21125B | 10mA~5A | 10A | 1000:1 2000:1 | 0.2,0.5 | ≤200 | 25 | L-W-H-J-A1-A2 80-22-69.5-68- 5.2-8 |

TR21126B | 10mA~5A | 10A | 1000:1 2000:1 | 0.2,0.5 | ≤500 | 45 | L-W-H-J-A1-A2 120-33-101.5- 98-5.2-8.5 |

TR21127B | 10mA~5A | 10A | 1000:1 2000:1 | 0.2,0.5 | ≤500 | 55 | L-W-H-J-A1-A2 150-35-126- 126-5.2-12 |

TR2174B | 10mA~5A | 10A | 1000:1 2000:1 | 0.2,0.5 | ≤500 | 35 | L-W-H-J-A1-A2 100-30-90- 83.5-5.2-9.5 |

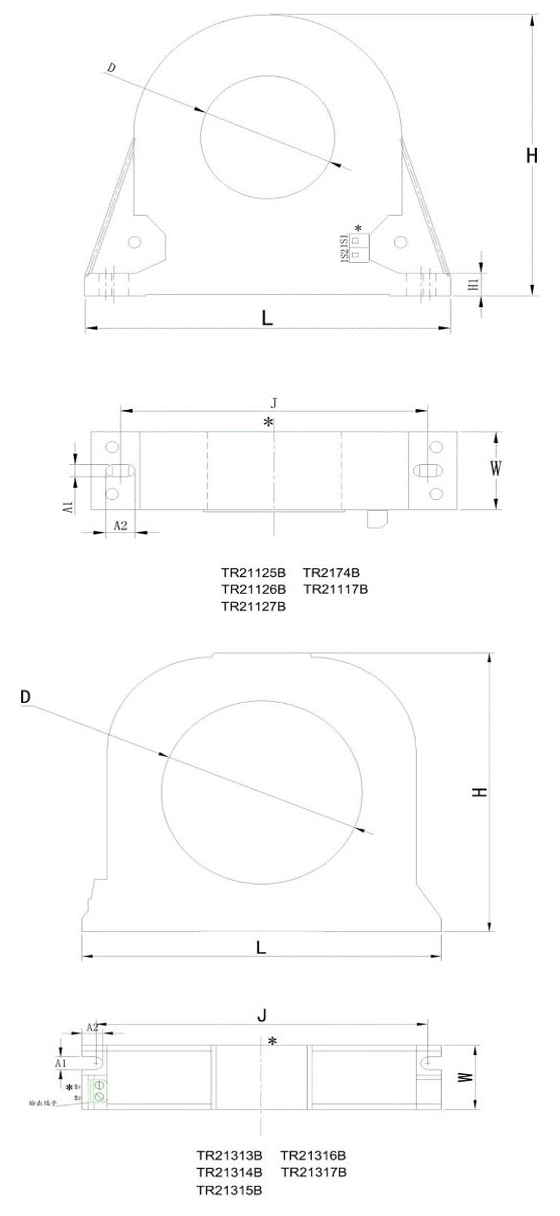

TR21313B | 10mA~5A | 10A | 1000:1 2000:1 | 0.2,0.5 | ≤500 | 32 | L-W-H-J-A1-A2 91-28-70-80- 5.5-7.5 |

TR21314B | 10mA~5A | 10A | 1000:1 2000:1 | 0.2,0.5 | ≤500 | 45 | L-W-H-J-A1-A2 104-28-83-93- 5.5-7.5 |

TR21315B | 10mA~5A | 10A | 1000:1 2000:1 | 0.2,0.5 | ≤500 | 65 | L-W-H-J-A1-A2 126-28-105- 115-5.5-7.5 |

TR21316B | 10mA~5A | 10A | 1000:1 2000:1 | 0.2,0.5 | ≤500 | 80 | L-W-H-J-A1-A2 143-28-122- 132-5.5-7.5 |

TR21317B | 10mA~5A | 10A | 1000:1 2000:1 | 0.2,0.5 | ≤500 | 105 | L-W-H-J-A1-A2 172-28-151- 161-5.5-7.5 |

TR21117B | 10mA~5A | 10A | 1000:1 2000:1 | 0.2,0.5 | ≤500 | 72 | L-W-H-J-A1-A2 175-42-150- 150-6.2-13 |

Outline Structure Diagram (Unit :mm)